As industries worldwide face mounting pressure to improve energy efficiency while maintaining production quality, the medium frequency induction heating machine has emerged as a technological game-changer. JKZ Induction Heating, with nearly three decades of specialization in electromagnetic heating solutions, has witnessed how these advanced systems are revolutionizing metal processing across global manufacturing sectors. From automotive component production to aerospace alloy treatment, the medium frequency induction heating machine delivers unprecedented performance advantages that traditional heating methods simply cannot match.

Precision Energy Deployment

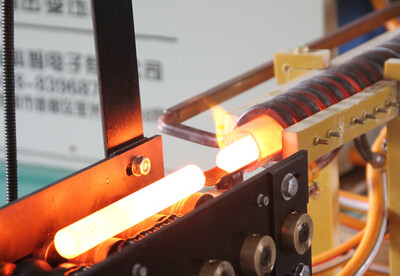

What sets the modern medium frequency induction heating machine apart is its ability to direct thermal energy with surgical precision. Unlike conventional heating methods that indiscriminately warm entire workpieces or surrounding air, induction technology focuses electromagnetic energy directly into targeted metal areas. This precision translates to remarkable energy savings—up to 60% less power consumption compared to resistance heating or gas furnaces in equivalent applications. The technology achieves this through controlled electromagnetic fields that induce currents only where needed, eliminating the wasteful heat dissipation common in traditional thermal processes. Our ISO-certified manufacturing processes ensure every JKZ machine maintains this efficiency throughout its operational lifespan.

The Efficiency Showdown

When comparing a medium frequency induction heating machine side-by-side with conventional heating systems, the performance differences become starkly apparent:

Traditional gas furnaces suffer from significant heat loss through exhaust gases and require lengthy preheating cycles, while induction systems reach operating temperature within minutes with zero standby energy costs. Where resistance heating elements degrade over time—leading to increasing power consumption—induction coils maintain consistent efficiency for years. Most dramatically, conventional methods often heat workpieces unevenly, requiring extended processing times to achieve target temperatures, whereas induction provides instant, uniform heating that reduces cycle times by up to 70%. These advantages combine to give induction heating a clear edge in both energy conservation and production throughput metrics.

Smart Controls for Optimized Consumption

Today's advanced medium frequency induction heating machine incorporates intelligent power management features that further enhance energy savings. Digital inverters automatically adjust frequency and current to match the specific electromagnetic properties of different metals, ensuring optimal energy transfer regardless of material. Smart sensors monitor temperature in real-time, modulating power output to maintain exact processing parameters without overshooting. These technological refinements, developed through JKZ's extensive R&D efforts, allow manufacturers to achieve perfect results while consuming the minimum energy necessary—a crucial advantage in today's cost-sensitive industrial environment.

Industry-Wide Impact on Sustainability

The transition to medium frequency induction heating machine technology represents more than just individual factory upgrades—it's driving a broader shift toward sustainable manufacturing. Automotive plants using induction for bearing race hardening reduce their carbon footprint while improving component quality. Aerospace suppliers adopting induction solutions for turbine blade heat treatment achieve better metallurgical results with lower energy budgets. Even traditional foundries switching from cupola furnaces to induction melting report energy savings exceeding 50% while achieving superior metal purity. These successes demonstrate how induction technology serves as a force multiplier for industrial energy conservation initiatives globally.

Future-Ready Manufacturing Infrastructure

As environmental regulations tighten and energy costs fluctuate, investing in a medium frequency induction heating machine positions manufacturers for long-term competitiveness. JKZ's CE-certified systems, backed by international service centers, provide the reliability needed for continuous operation while future-proofing facilities against rising energy expenses. The technology's scalability—from small workstations to integrated production lines—allows gradual implementation matching business growth. With applications expanding into renewable energy component manufacturing and electric vehicle production, induction heating is proving indispensable for next-generation industrial processes.

For nearly 30 years, JKZ Induction Heating has refined medium frequency induction heating machine technology to help manufacturers worldwide achieve their efficiency goals without compromising quality. From initial consultation to ongoing technical support, our team provides complete solutions tailored to each client's specific energy-saving and production needs.

en

en  cn

cn  jp

jp  ko

ko  de

de  es

es  it

it  ru

ru  pt

pt  th

th  vi

vi  pl

pl

Call us on:

Call us on:  Email Us:

Email Us:  NO. 688th South Baoguang Road, Xindu District, Chengdu City, Sichuan Province, China

NO. 688th South Baoguang Road, Xindu District, Chengdu City, Sichuan Province, China