JKZ induction heater has also been widely used in the oil and gas industry. In the situations like pipeline laying process, the application of pre-weld heat treatment, post-weld heat treatment, oil pipeline insulation, and brazing of various drill bit carbides, you can always find the existence of oil and pipelines induction heating. The place where the induction equipment appears most frequently, especially in the heat treatment of welding, is the working field where the water source is far away and the equipment that has high flexibility and convenient heating is needed. To achieve better oil and pipelines induction, JKZ has developed a special air-cooled equipment in accordance with the customer's application scenarios, so as to prevent the problem of the traditional equipment requiring water cooling from happening. Moreover, the sensor of our air-cooled heater is designed with a flexible cable that can be wound around pipes of different diameters; thus, ther air-cooled induction heater produced by JKZ has now gradually become one of the most popular products among our customers. Designed to meet the requirements of long holding time, JKZ's induction heating machine for oil and gas industries uses advanced software control and preset heating curve. You can easily conduct a heating process of several hours just with a single finger operation.

Advantages of Induction Heating in Oil and Gas

Energy saving

Reduce processing time

Temperature control

Control and local heating

Potential as an integrated assembly line

No physical contact

Improve the working environment

How Induction Heating is used in the Oil and Gas Industry?

Drilling tools-brazing and disassembling carbide blades

Adhesive curing and coating repair of oil and gas pipelines and steel pipes

Induction heating for pipe bending or forming

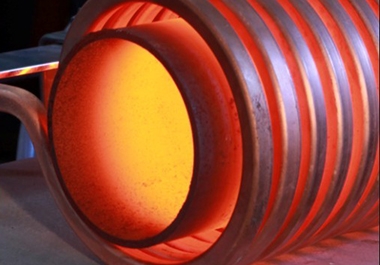

Heat treatment and hardening of shafts and tube ends

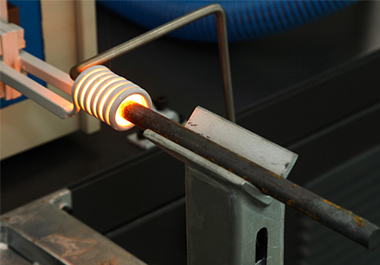

Used for induction preheating of welded steel pipes on drilling rigs and pipelines

Preheating and stress relief of welding seams of oil tanks or drilling rigs

Pedestal heating for biomass processing for biofuel production

en

en  cn

cn  jp

jp  ko

ko  de

de  es

es  it

it  ru

ru  pt

pt  th

th  vi

vi  pl

pl

Call us on:

Call us on:  Email Us:

Email Us:  NO. 688th South Baoguang Road, Xindu District, Chengdu City, Sichuan Province, China

NO. 688th South Baoguang Road, Xindu District, Chengdu City, Sichuan Province, China