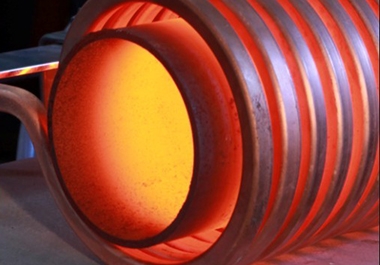

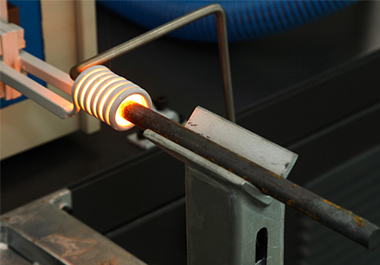

Hot nesting is a process that is used in many industries. It especially has many applications in bearing manufacturing, shaft workpieces installation and fixation, and even the replacement of cutter heads for CNC tools, hot assembly, and hot disassembly. In the industrial mechanical manufacturing process, it is often necessary to assemble and disassemble other metal accessories on the shaft/sleeves workpiece. These accessories are generally assembled and disassembled by thermal expansion, such as the installation and disassemble of bearings, shafts, sleeves, tubes, hard alloy parts and the hot fitting of CNC machine tool heads, etc. The unique precision heating effect of induction heating equipment provides an excellent solution for the hot fitting process. The induction heating machine coil can be designed exactly according to the various metal workpiece shape and dimension. Moreover, the induction heating generator can also accurately control the output power in accordance with different heating speed needs. It allows the heating to be exactly focusing on the target heating zone. Because of the special features of the induction heating, more and more factories are now starting to use induction heating technology as a means of installation and disassembly. Induction heating equipment can quickly and conveniently heat the target area required by customers.

en

en  cn

cn  jp

jp  ko

ko  de

de  es

es  it

it  ru

ru  pt

pt  th

th  vi

vi  pl

pl

Call us on:

Call us on:  Email Us:

Email Us:  NO. 688th South Baoguang Road, Xindu District, Chengdu City, Sichuan Province, China

NO. 688th South Baoguang Road, Xindu District, Chengdu City, Sichuan Province, China