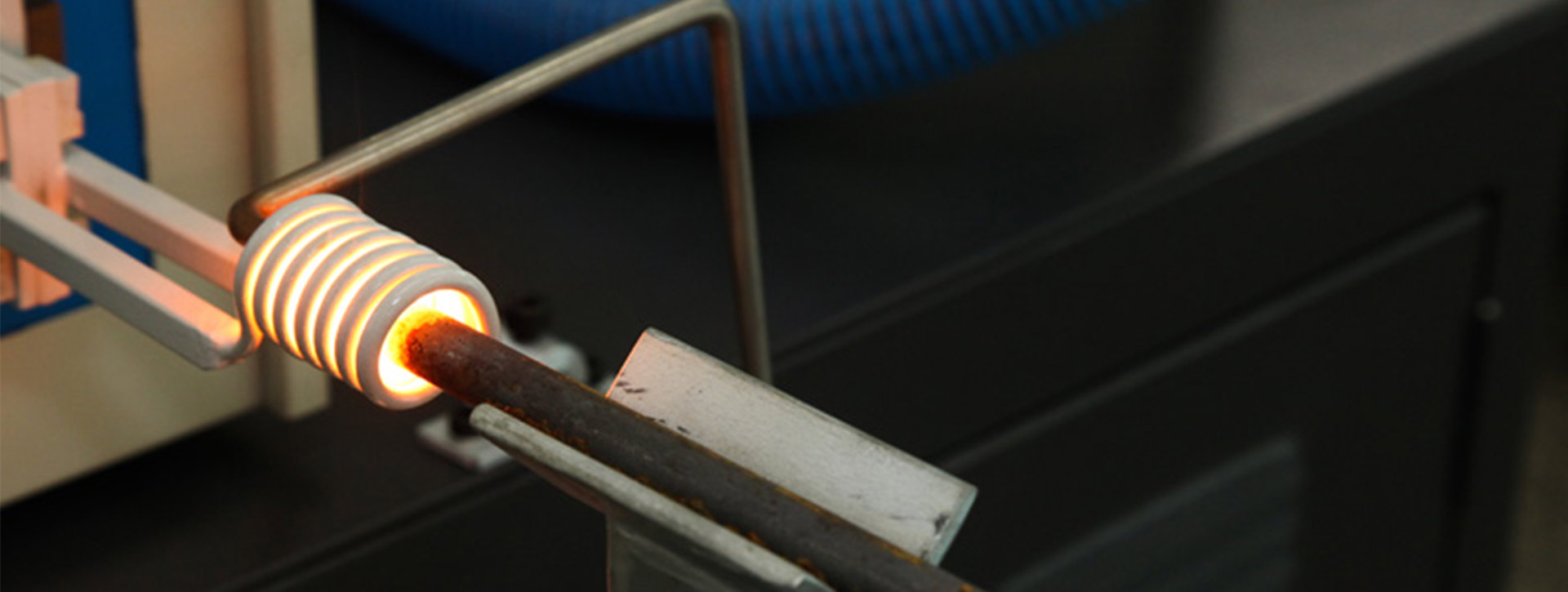

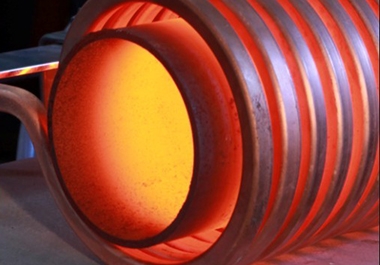

High-frequency induction is a method of heating electrically conductive materials using electromagnetic induction at relatively high frequencies. This process relies on the principles of electromagnetic fields and the high-frequency eddy current heating effect to generate heat within the material being heated.

-

Products

-

Industries

- Automotive Industry

- Fastener Manufacturing

- Tube And Pipe Heating

- Railway

- Agricultural Equipment

- Wire And Cable

- Oil And Gas

- Carbide Production

- Metal And Foundry

- Jewelry And Minting

- Shrink Fitting

- Shipbuilding

- Mining

- Aviation And Aerospace

- Chemical And Pharmaceutical Industry

-

Application

- Spring Heating

- Pipe And Tube Production

- Induction Hardening

- Induction Annealing And Normalizing

- Induction Wire And Cable Heating

- Induction Preheating

- Induction Post Weld Heat Treatment (PWHT)

- Wooden Carbide Brazing

- Stone Saw Blade Brazing

- Lathe Tool Brazing

- Non-Ferrous Metal Induction Melting

- Steel Melting

- Precious Metal Melting

- Induction Shrink Fitting

-

Services

- Company

- Resources & Insights

- Contact Us

en

en  cn

cn  jp

jp  ko

ko  de

de  es

es  it

it  ru

ru  pt

pt  vi

vi  th

th  pl

pl

Call us on:

Call us on:  Email Us:

Email Us:  NO. 688th South Baoguang Road, Xindu District, Chengdu City, Sichuan Province, China

NO. 688th South Baoguang Road, Xindu District, Chengdu City, Sichuan Province, China