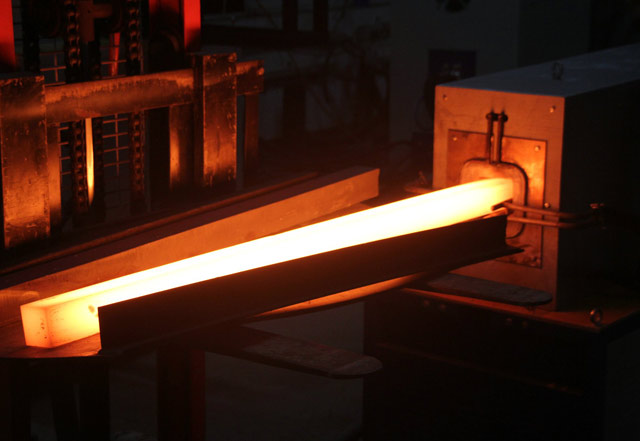

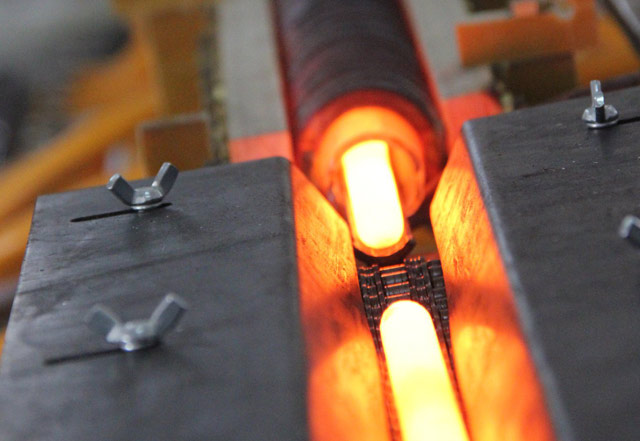

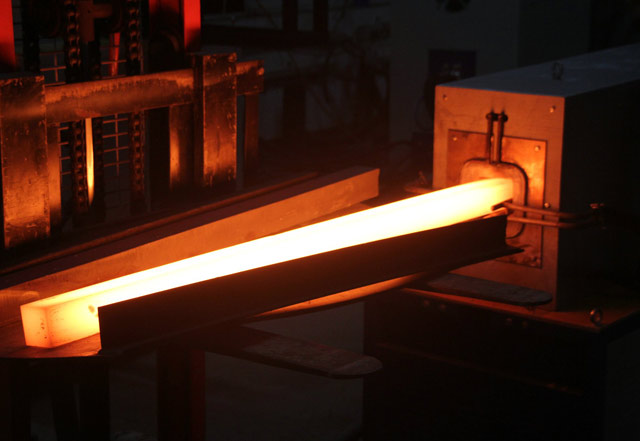

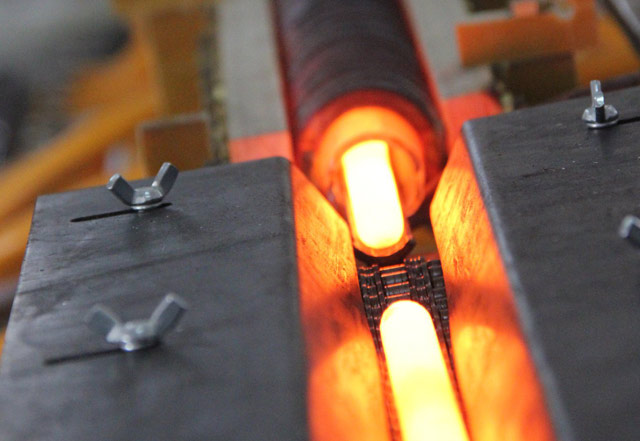

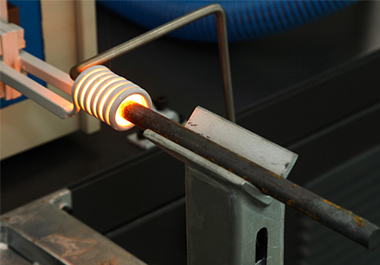

Most of the fasteners are formed by hot forging. In the fasteners' production process, they have strict requests for the heating speed for the hot forging and hot bending.

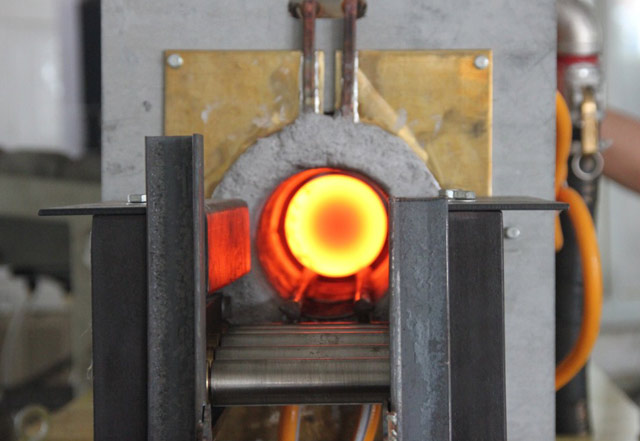

Normally, the induction heating equipment heats up quickly, and the workpiece can reach the forging temperature within just a few seconds. Thus, the surface of the workpiece processed by induction heating devices is normally less oxidized, and its bolt quality can be more guaranteed; using professional induction heating equipment is also easy to realize automatic operation, thereby greatly improving efficiency. Moreover, since the induction heating unit usually occupies a small area, it can also be placed directly on the side of the punch.

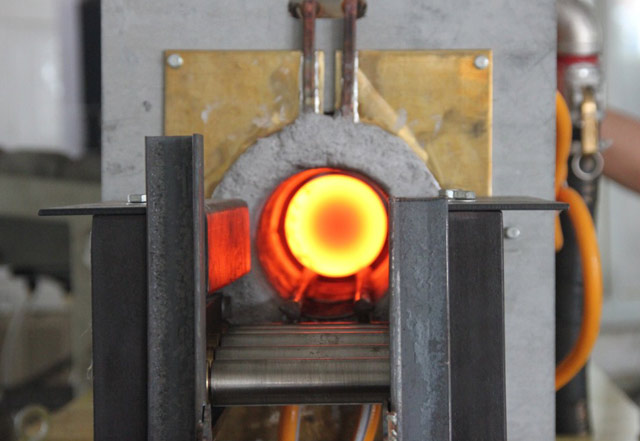

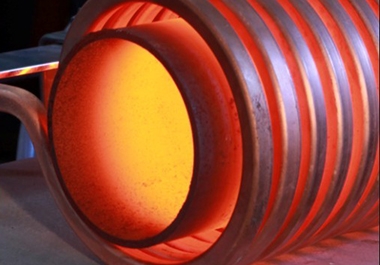

As for the usage of the induction heater, there is no need to open the furnace for preheating and burn as you use it. Thus, you can use the heater whenever you want and there will be no waste. Capable of accurately controlling the working temperature, JKZ's induction heating devices can significantly improve the workplace environment, eliminate heat, smoke and noise, and reduce pollution. Generally, the more accurate the heating temperature, the more stable the product quality.

JKZ's induction heating equipment is deeply rooted in the forging industry. In terms of equipment selection, we normally establish equipment selection models based on comprehensive factors such as customer's billet heating cross-sectional area, heating length, and existing or ready-to-coordinate on-site production equipment. Combining different application scenarios, we srtive to provide our customers with the best selection of CX / SWS / MFS series induction heating equipment.

en

en  cn

cn  jp

jp  ko

ko  de

de  es

es  it

it  ru

ru  pt

pt  th

th  vi

vi  pl

pl

Call us on:

Call us on:  Email Us:

Email Us:  NO. 688th South Baoguang Road, Xindu District, Chengdu City, Sichuan Province, China

NO. 688th South Baoguang Road, Xindu District, Chengdu City, Sichuan Province, China