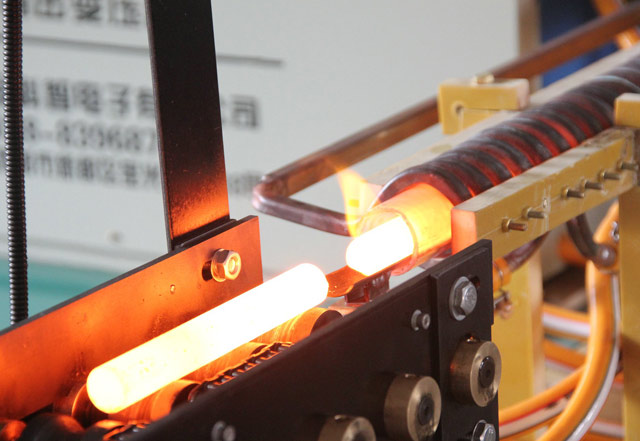

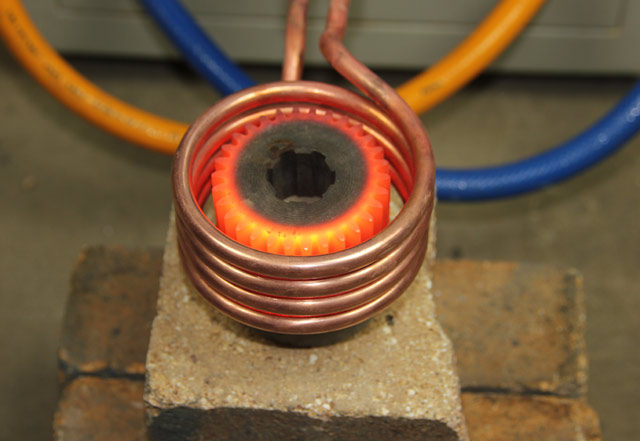

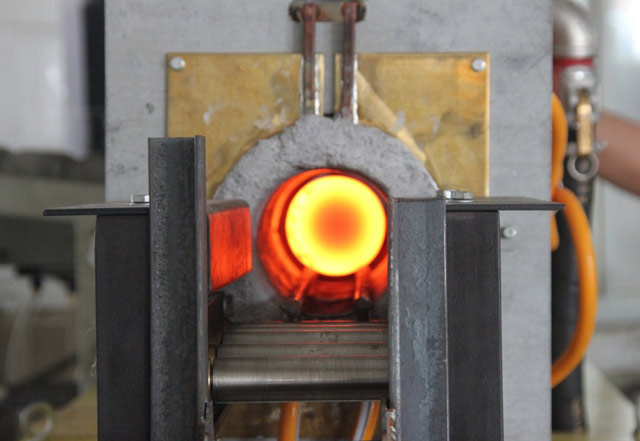

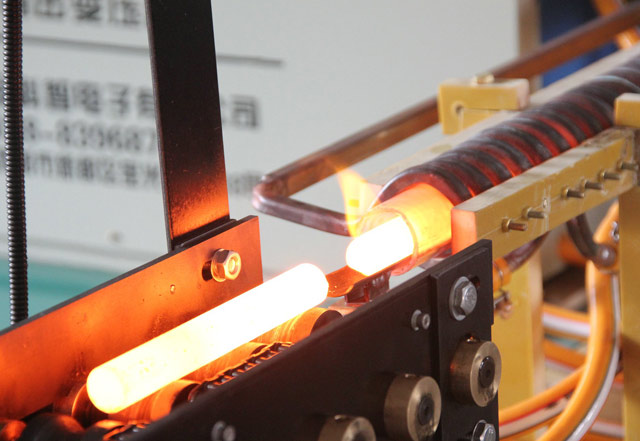

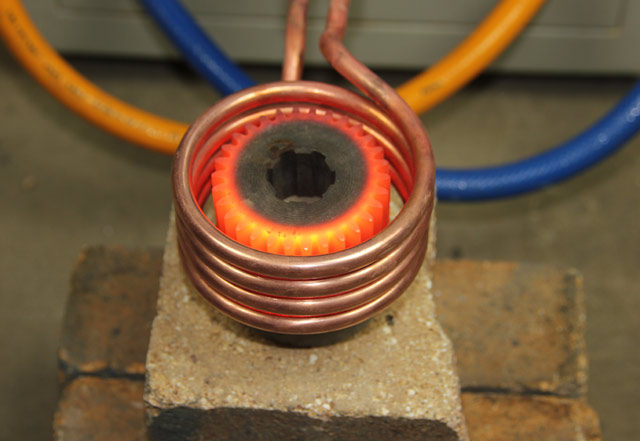

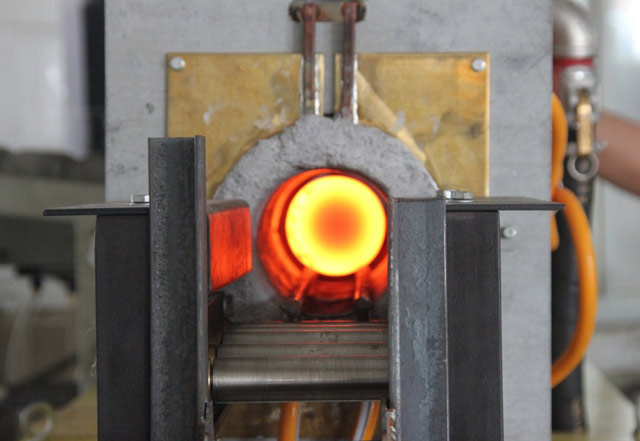

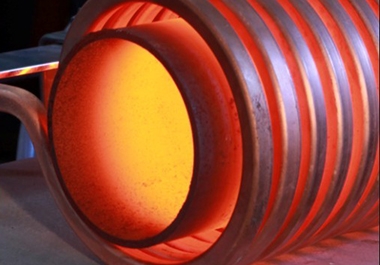

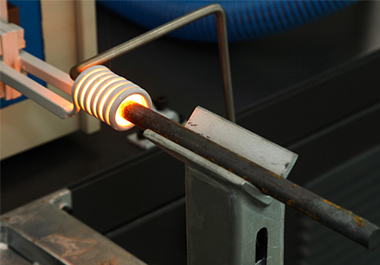

The automobile manufacturing industry is the most typical and core application field of JKZ induction heating equipment. Situations like shafts surface hardening, tube inner bore hardening, sprockets teeth hardening, gear teeth hardening, ball head surface hardening, fork teeth hardening, brake pads hardening, camshafts hardening, and chain hardening all need the help of professional automotive induction heaters. Since automobile and motorcycle parts products have a huge number and specifications, and these accessories have very different process requirements for the production process, JKZ's induction rod heater that covers the frequency range from 1Khz -120KHz is then naturally becoming an excellent choice for various factories as it can complete various treatment processes in automotive industry simultaneously. Moreover, the power of JKZ's automotive induction heater can support up to 600Kw of a single machine. Desgined by the professional R&D team at JKZ, all of our automotive induction heaters and industrial induction melting machine hold the advantages of high safety, energy-saving, easy automation control, easy maintenance, high-cost performance, long use life, and small install space. As for the working process of JKZ's induction heating products in automotive industry, hot forging is usually employed at the beginning of manufacturing. In the later stage, heat treatment of surface quenching and tempering are widely used.

en

en  cn

cn  jp

jp  ko

ko  de

de  es

es  it

it  ru

ru  pt

pt  th

th  vi

vi  pl

pl

Call us on:

Call us on:  Email Us:

Email Us:  NO. 688th South Baoguang Road, Xindu District, Chengdu City, Sichuan Province, China

NO. 688th South Baoguang Road, Xindu District, Chengdu City, Sichuan Province, China