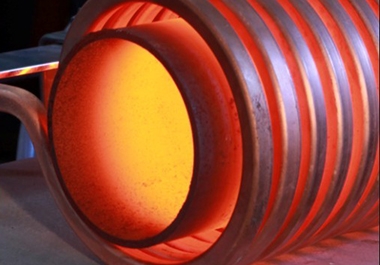

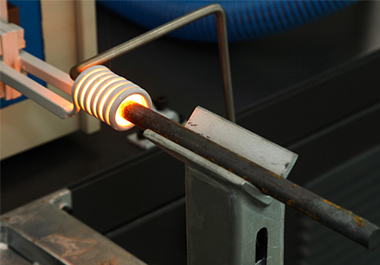

Hard alloy carbide is an important raw material for cutter heads. At present, most of the manufacture of cemented carbide cutting tools uses high-frequency induction heating brazing technology. Due to the special structure of some cemented carbide tools, it is necessary to strictly control the welding heating area to prevent the parts that do not need to be heated from being heated so as to eventually ensure the manufacturing technical requirements of the tool. In the process of combining alloy cutter heads, diamond cutter heads and cutter bodies, brazing is one of many combinations. Induction heating equipment can complete brazing or hot clamping of cutter head with the help of soldering material. Under the premise of fully protecting the original properties of the metal material, the cutter head and the cutter body can be easily combined together, which greatly reduces the customer's use and maintenance costs, and has been unanimously recognized by the industry.

en

en  cn

cn  jp

jp  ko

ko  de

de  es

es  it

it  ru

ru  pt

pt  th

th  vi

vi  pl

pl

Call us on:

Call us on:  Email Us:

Email Us:  NO. 688th South Baoguang Road, Xindu District, Chengdu City, Sichuan Province, China

NO. 688th South Baoguang Road, Xindu District, Chengdu City, Sichuan Province, China