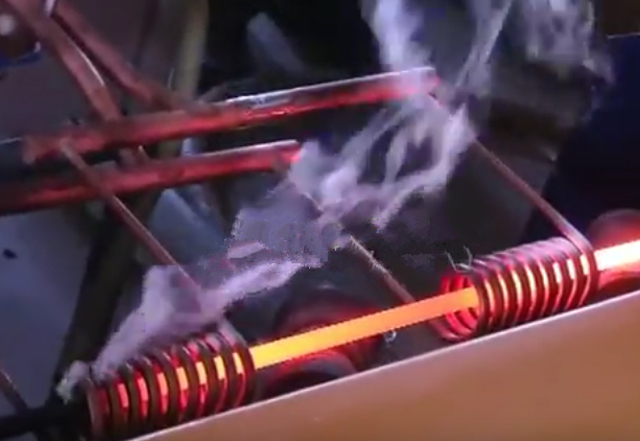

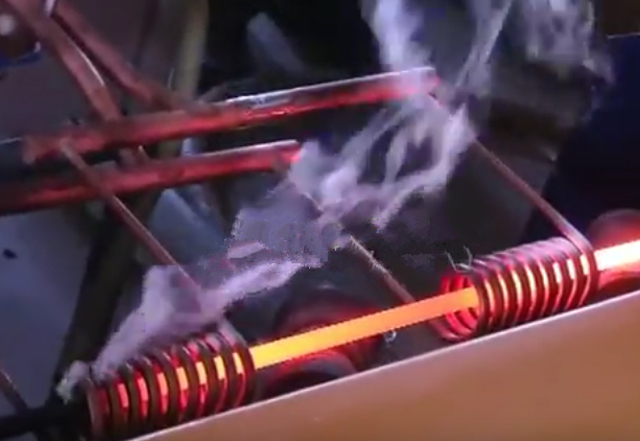

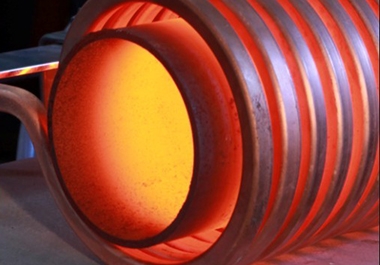

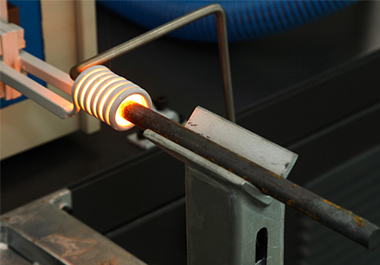

Induction annealing and induction tempering are very important processes in the heat treatment of the metal workpiece. These two processes can effectively change the hardness of the processed metal materials so as to meet different industry production requests. In the situations like steel wire annealing, spring wires annealing, tube annealing, shafts surface heating, gear teeth hardening, and sleeves inner bore heating, you can all find the existence of induction/wire annealing machines. Through annealing/tempering induction heat treatment, the performance of the workpiece can be much improved according to the customer's technical requirements to meet the process requirements of the workpiece. As a professional induction heating machine manufacturer in China, JKZ can provide you with both MOSFET and IGBT inverter types induction annealing machines with a frequency range from 1KHz to 120KHz. We also sell single wire annealing machines with the power range of 7.5KW to 600KW in case you need to deal with the heating of workpieces of different shapes and different materials. For instance, with our wire annealing machines, you can easily process metals like carbon steel, stainless steel, copper, brass materials, titanium, metal parts like automotive parts, shafts, gears, sprockets, etc. Aiming to meet the requirements of various remote control PLCs and temperature control systems, JKZ's induction heating machines can perfectly meet our customers' heating requirements to the greatest extent.

en

en  cn

cn  jp

jp  ko

ko  de

de  es

es  it

it  ru

ru  pt

pt  th

th  vi

vi  pl

pl

Call us on:

Call us on:  Email Us:

Email Us:  NO. 688th South Baoguang Road, Xindu District, Chengdu City, Sichuan Province, China

NO. 688th South Baoguang Road, Xindu District, Chengdu City, Sichuan Province, China