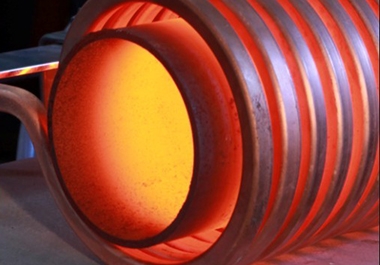

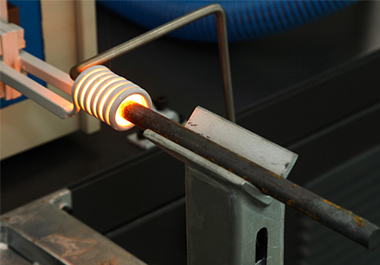

The railway industry has a huge demand for induction heating equipment. We can see the help of induction heating equipment in the production of thousands of parts from small to spikes, rail casting and drawing, and the head/carriage. Basic applications such as forging, brazing, quenching, and tempering are used in various factories in the railway industry. With the frequency range from 1KHZ to 120KHZ, JKZ's induction heating equipment can power up to 600Kw. While the medium frequency induction furnace is mainly used for the forging of rails, the high frequency induction heater is more used for welding, quenching, annealing, pre welding heating, post welding heating and other heat treatments. Induction heating equipment has fast heating speed, a high degree of automation, simple maintenance, long application life, small size, convenient installation, and convenient movement. It is suitable for small road studs, gears that are as large as the heating requirements of drive shafts, wheels, and rails.

en

en  cn

cn  jp

jp  ko

ko  de

de  es

es  it

it  ru

ru  pt

pt  th

th  vi

vi  pl

pl

Call us on:

Call us on:  Email Us:

Email Us:  NO. 688th South Baoguang Road, Xindu District, Chengdu City, Sichuan Province, China

NO. 688th South Baoguang Road, Xindu District, Chengdu City, Sichuan Province, China