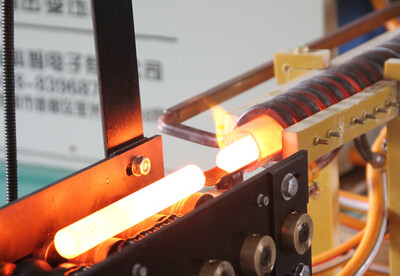

In the precision-driven world of aerospace manufacturing, where material integrity and component reliability are paramount, high frequency induction heater from JKZ have emerged as transformative solutions. With nearly three decades of induction heating expertise, JKZ's advanced heating technology meets the stringent demands of aircraft component production, delivering unmatched precision and repeatability.

Precision Component Heat Treatment in Aerospace Applications

Aerospace-grade alloys demand exacting thermal processing to achieve optimal mechanical properties. JKZ's high frequency induction heater provide localized, controlled heating for critical aircraft components like turbine blades, landing gear parts, and structural elements. The technology's ability to maintain temperatures within ±2°C ensures uniform material transformation while preventing distortion - a crucial factor in maintaining tight tolerances for flight-critical parts. Our ISO-certified systems integrate seamlessly with aerospace production lines, supporting both prototyping and high-volume manufacturing.

Induction Heating vs Traditional Aerospace Thermal Processes

The aerospace industry traditionally relied on furnace treatments and flame heating, but JKZ's high frequency induction heater technology offers compelling advantages:

Selective heating preserves base material properties in adjacent areas

Reduced processing times increase production throughput by up to 80%

Energy efficiency improvements of 40-60% compared to conventional methods

Superior process control eliminates the risk of overheating sensitive alloys

These benefits make induction heating particularly valuable for thin-walled aerospace components where precise heat affected zone control is essential.

Innovative Solutions for Aircraft Maintenance and Repair

Beyond manufacturing, JKZ's high frequency induction heater play a vital role in aircraft maintenance operations. The portable units enable on-wing repair of components like hydraulic fittings and structural elements, reducing aircraft downtime significantly. The technology's precise temperature control prevents damage to surrounding composite materials - a critical consideration in modern airframe maintenance. Our CE-certified systems are increasingly adopted by MRO facilities worldwide for their reliability and ease of integration into existing repair processes.

Lightweight Alloy Processing with High Frequency Induction

Modern aerospace designs increasingly utilize titanium and aluminum alloys to reduce weight while maintaining strength. JKZ's high frequency induction heater are ideally suited for processing these challenging materials, offering:

Rapid, uniform heating that prevents grain growth in titanium components

Accurate temperature profiling for aluminum alloy heat treatment

Custom coil designs that accommodate complex aircraft part geometries

Our dedicated R&D team continuously refines these solutions to meet evolving aerospace material requirements.

Backed by 30 years of experience and a global service network across twenty countries, JKZ remains at the forefront of induction heating innovation for the aerospace sector.

en

en  cn

cn  jp

jp  ko

ko  de

de  es

es  it

it  ru

ru  pt

pt  th

th  vi

vi  pl

pl

Call us on:

Call us on:  Email Us:

Email Us:  NO. 688th South Baoguang Road, Xindu District, Chengdu City, Sichuan Province, China

NO. 688th South Baoguang Road, Xindu District, Chengdu City, Sichuan Province, China