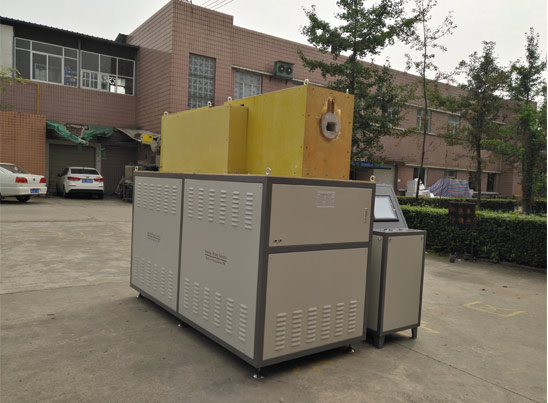

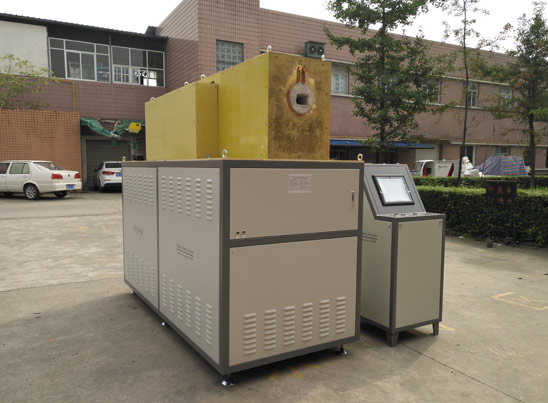

MFS-160A medium frequency induction heating machine inverter uses IGBT as the core component. The heating furnace frequency is designed according to the size of the workpiece, ranging from 1KHZ to 10KHZ. As a member of the MFS series, MFS-160A's single set maximum power can reach 600KW, and it uses standard voltage 3 Phases 380V/50HZ. Special voltage standard for this device is also available for further customized design.

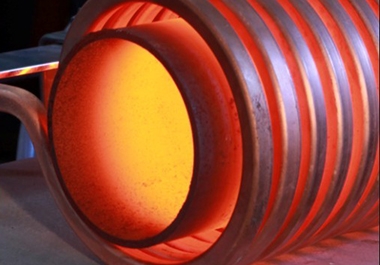

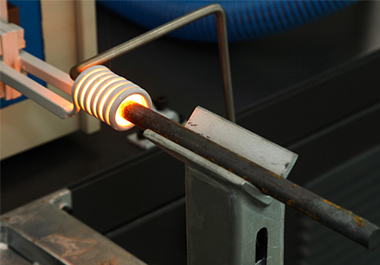

The applications of this medium frequency induction furnace are billets forging heating such as auto parts production and heat treatment surface hardening like the shafts, gears, metal melting furnace, tube bending, and elbow making.

Adopting touch screens with the embedded program, MFS-160A can also reduce the difficulty of the operation.

JKZ also provides vertical and horizontal designs according to the customers' installation situations.

en

en  cn

cn  jp

jp  ko

ko  de

de  es

es  it

it  ru

ru  pt

pt  th

th  vi

vi  pl

pl

Call us on:

Call us on:  Email Us:

Email Us:  NO. 688th South Baoguang Road, Xindu District, Chengdu City, Sichuan Province, China

NO. 688th South Baoguang Road, Xindu District, Chengdu City, Sichuan Province, China