In modern metal heat treatment and forging industries, medium-frequency induction heating machines have become an indispensable core equipment. With advantages such as fast heating speed, high efficiency, low energy consumption, and precise control, they are widely used in various industrial fields like billet heating, metal forging, smelting, and heat treatment. As a professional manufacturer in this field, JKZ is continuously committed to the development and optimization of medium-frequency heating equipment, providing reliable, high-performance induction heating solutions.

Working Principle of Medium-Frequency Induction Heating Machine

The fundamental principle of a medium-frequency induction heating machine is electromagnetic induction heating. The working process includes:

Converting the mains frequency (50Hz) AC power to DC through a rectifier;

Then converting the DC to medium-frequency AC power in the range of 300Hz to 20kHz through an inverter;

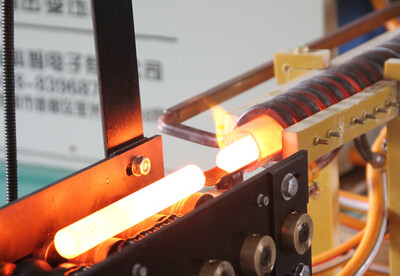

The medium-frequency current flows through the induction coil, generating high-density magnetic field lines;

The metal material is placed inside the induction coil, where the magnetic field lines cut through the metal, generating eddy currents;

The eddy currents are converted to resistive heat within the metal, achieving rapid and uniform heating.

Through this process, the medium-frequency induction heating machines can precisely control the heating area and temperature, avoiding the large temperature differences and low thermal efficiency associated with traditional flame heating methods.

Main Applications of Medium-Frequency Induction Heating Machine

Preheating and Rolling Processing of Billets: In steel rolling and forging processes, billets need to be preheated to a certain temperature to improve plasticity and reduce processing resistance. The medium-frequency induction heater machine can quickly and uniformly heat the billets, ensuring stable physical properties during subsequent processing, thus improving product quality.

Metal Forging Heating: Preheating before metal forging is a crucial step. Using a medium-frequency induction heater machine can significantly enhance the toughness and plasticity of metal billets, making the forging process smoother and reducing the occurrence of cracks and defects.

Metal Smelting: For the melting processes of metals such as copper, aluminum, and steel, the medium-frequency induction heating machine offers fast melting speeds and precise temperature control, making it widely used in alloy preparation and casting factories.

Metal Heat Treatment Processes: Quenching, annealing, tempering, and other heat treatment steps are crucial to improving the performance of metals. The medium-frequency induction heating machine, through non-contact heating methods, can achieve pinpoint and specific temperature heat treatment of both the surface and deep layers of workpieces, enhancing hardness, toughness, and fatigue resistance.

Pipe and Wire Heating Processing: In the pre-processing steps of forming, bending, and welding metal pipes and wires, the medium-frequency induction heater machine is used for continuous heating of materials, effectively improving processing precision and efficiency.

Operational Advantages of Medium-Frequency Induction Heating Machine

With increasing demands for environmental protection and industrial intelligence, medium-frequency induction heater machines are increasingly favored by the industry for their green, efficient, and intelligent characteristics:

No Open Flame Pollution: The heating process involves no smoke, wastewater, or waste gas emissions, greatly improving the working environment;

Simple Operation, Safe and Reliable: Equipped with a digital control system, the operation is intuitive with high safety performance;

Energy Efficient: Compared to traditional gas or resistance furnace heating methods, the energy-saving effect is significant;

Easy Maintenance: The modular design makes it easy to repair and replace parts, reducing operating costs.

As a professional manufacturer of induction heating equipment, JKZ has many years of design and application experience in the field of medium-frequency induction heater machine. Our products cover a wide range of scenarios from small metal processing to large industrial manufacturing. The company provides comprehensive services from model selection consultation, scheme design, equipment manufacturing to after-sales maintenance, ensuring that users can achieve stable and reliable heating effects and continuous high-efficiency production capabilities. The medium-frequency induction heating machine not only has mature technology and wide applicability but also represents the development direction of modern metal heating processes. In the future, with the continuous improvement of automation levels and environmental standards, this equipment will play a key role in more industrial fields.

en

en  cn

cn  jp

jp  ko

ko  de

de  es

es  it

it  ru

ru  pt

pt  th

th  vi

vi  pl

pl

Call us on:

Call us on:  Email Us:

Email Us:  NO. 688th South Baoguang Road, Xindu District, Chengdu City, Sichuan Province, China

NO. 688th South Baoguang Road, Xindu District, Chengdu City, Sichuan Province, China