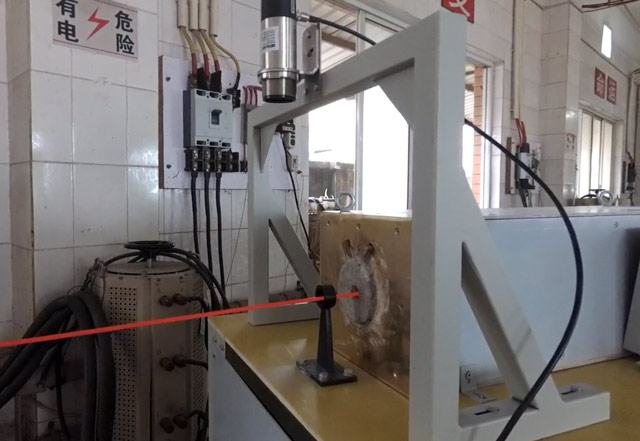

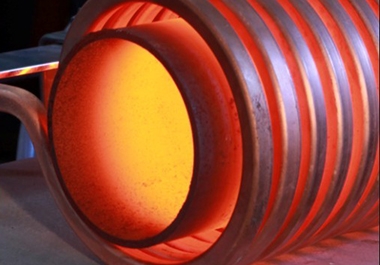

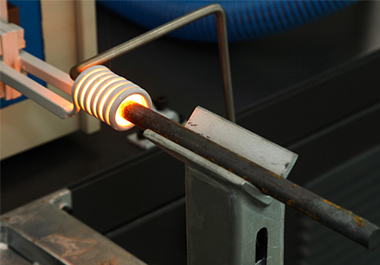

A lot of cables need to be heat-treated before further processing. There is a lot of request about the online induction heating wire with fast speed, different temperature range, accurate power output, and temperature control on small diameter wires; thus, a precision heating method is a must for the wire and cable industries. To solve this problem, the induction heating equipment with the feature of a high degree of automation operation has made its entance. In order to assist factories in producing high-quality induction heating wires, JKZ's induction heating machines all have the characteristics of flexible setting of time, temperature and power, accepting remote control of start/stop, flexible power adjustment, long working time (24 hours working/day), fast power output, high heating efficiency, and fast machine shutdown according to the temperature control signal. With accurate temperature control, JKZ's induction heating machine is very suitable for the heating of wires and cables during the heat treatment. Whether it is annealing straightening or post-quenching, JKZ has rich experience. Whether you need to heat the wire or just heat it as thick as rebar, we can always provide you with a complete solution, and we can also cooperate with other suppliers to provide you with complete equipment for online heating of steel wires or steel bars. Different sizes of billet heating require different frequencies and powers. JKZ's induction heating equipment family covers the frequency range of 1-120KHz, which can be greatly adapted to customer needs.

en

en  cn

cn  jp

jp  ko

ko  de

de  es

es  it

it  ru

ru  pt

pt  th

th  vi

vi  pl

pl

Call us on:

Call us on:  Email Us:

Email Us:  NO. 688th South Baoguang Road, Xindu District, Chengdu City, Sichuan Province, China

NO. 688th South Baoguang Road, Xindu District, Chengdu City, Sichuan Province, China