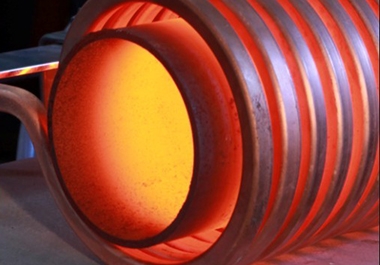

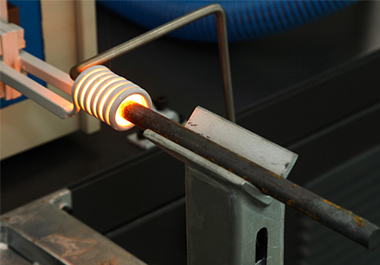

In the production process of pipelines, basic processes such as thermal deformation, welding, and heat treatment are indispensable. After buying the pipeline, many users will further process the pipeline according to their actual needs, such as changing the diameter and wall thickness, conducting partial deformation and other higher requirements of heat treatment. As a professional induction heating machine manufacturer, JKZ sells various induction heating equipment with different power ranging from 7.5KW to 600KW, and these induction heating products can heat different pipelines with different wall thickness. To realize accurate temperature control in case the heater users have a varied heat-treatment process, all of our induction heating devices can conduct precise control of their output power from 1% to 100%. In the process of automated online production, the advantages of induction heating are even more prominent than that of many other types of equipment. Capable of fast starting up and shutting down according to remote signal control, more and more customers have now started to use induction heating equipment as the heating source in the pipeline manufacturing process so as to greatly improve the production efficiency.

en

en  cn

cn  jp

jp  ko

ko  de

de  es

es  it

it  ru

ru  pt

pt  th

th  vi

vi  pl

pl

Call us on:

Call us on:  Email Us:

Email Us:  NO. 688th South Baoguang Road, Xindu District, Chengdu City, Sichuan Province, China

NO. 688th South Baoguang Road, Xindu District, Chengdu City, Sichuan Province, China