In modern industrial manufacturing, welding technology is widely used in the processing and maintenance of structural components such as oil pipelines, chemical storage tanks, and mechanical equipment. In order to improve welding quality and reduce the risk of weld cracks, preheating treatment before welding has become an essential step. In this process, the role of the pre-heating machine is particularly critical.

Significance of Welding Preheating

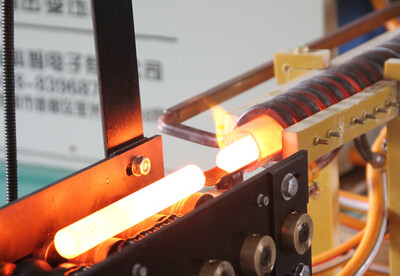

Preheating before welding involves heating the weld and the area nearby to reduce the thermal stress generated during welding, thus avoiding cold cracks. This is particularly important for high carbon steel, alloy steel, and large workpieces with complex structures. Traditional preheating methods such as open flame, hot air, or resistance heating often have low efficiency, inaccurate control, and even certain safety hazards. The pre-heating machine uses electromagnetic induction heating, which not only heats quickly but is also safe and environmentally friendly, making it an ideal choice for modern welding procedures.

Technical Advantages of the Pre-Heating Machine

The pre-heating machine is designed for on-site use in the welding field, especially suitable for oil and gas pipeline welding, chemical storage tank repair, and preheating of various large and irregular workpieces. Its main advantages are reflected in the following aspects:

No water cooling system required: JKZ's pre-heating machine is equipped with an air cooling system, not relying on a water source, suitable for various complex outdoor environments;

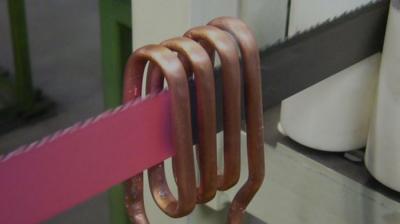

Flexible heating cables: can be freely wound according to the shape of the workpiece, suitable for various sizes and structures;

Precise control of temperature and time: Through an intelligent control system, precise management of the heating process is achieved, ensuring uniform preheating that meets process requirements;

Easy to move and deploy: The equipment is small and lightweight, making it easy to quickly move and use at the construction site;

Energy-efficient and efficient: By using induction heating, heat loss is reduced, and energy efficiency is improved.

Practical Application Scenarios

In the petrochemical industry, pipeline systems are often widely distributed with varying diameters, and the on-site construction environment is complex. JKZ's pre-heating machine can achieve rapid preheating of workpieces with different diameters and shapes by extending heating cables and flexibly winding induction coils. In addition, for large pressure vessels and storage tank welding, the workpieces are huge and have special shapes, making it challenging for traditional heating methods to meet the requirements of uniform heating.

As the requirements for welding quality and construction efficiency continue to increase, traditional preheating methods are no longer able to meet the needs of modern manufacturing. JKZ's pre-heating machine, with its efficient, safe, flexible, and precise advantages, is gradually replacing traditional equipment, becoming an indispensable heating tool in industrial welding. In the future, pre-heating machines will play a greater role in more industrial fields, helping welding technology move towards intelligent and high-quality development.

en

en  cn

cn  jp

jp  ko

ko  de

de  es

es  it

it  ru

ru  pt

pt  th

th  vi

vi  pl

pl

Call us on:

Call us on:  Email Us:

Email Us:  NO. 688th South Baoguang Road, Xindu District, Chengdu City, Sichuan Province, China

NO. 688th South Baoguang Road, Xindu District, Chengdu City, Sichuan Province, China